Build a Smarter Brand by Using AI Manufacturing

Build a smarter, future-ready brand with AI in manufacturing. Improve quality, reduce costs, and boost efficiency through intelligent automation and insights.

As a business owner, I’m always looking for ways to make my brand more efficient, innovative, and competitive. That’s where AI manufacturing comes in. By using artificial intelligence trends, I can streamline production, improve quality, and make smarter decisions based on real-time data. It’s not just about machines doing more work. It’s about using technology to build a smarter, more responsive brand that can grow and adapt in today’s fast-changing world.

What Is AI Manufacturing?

AI manufacturing means using smart technology to improve how I run my production. It helps me work more efficiently, reduce errors, and make better decisions based on real-time data. It’s not just about having robots in the factory. It’s about using intelligent systems that learn from patterns, adapt to changes, and keep improving how everything runs. This allows me to save time, lower costs, and deliver higher-quality products to my customers.

Common AI Applications in Manufacturing:

-

Real-time quality checks using computer vision

-

Demand forecasting based on historical and real-time data

-

Predictive maintenance that prevents machine breakdowns

-

Automated production scheduling and inventory planning

-

AI-based robotics for precision tasks

How Smart Manufacturing Builds Stronger Brands

-

It helps me reduce waste and cut costs by optimizing production.

-

I can deliver products faster and more reliably to my customers.

-

Real-time data allows me to make better, quicker decisions.

-

I can improve product quality with fewer errors and defects.

-

My operations become more flexible and can adapt to demand changes.

-

It shows my brand is forward-thinking, innovative, and trustworthy.

Why AI Matters for Building a Stronger Brand

Your brand is only as strong as your product. If your output is inconsistent or your delivery unreliable, your branding and advertising can’t fix that. AI manufacturing ensures that operational excellence becomes part of your identity.

How AI Enhances Brand Value:

-

Quality Consistency: AI-powered quality control systems catch defects early, ensuring customers always get what they expect.

-

Responsiveness: Faster decision-making and smarter forecasting mean you can react quickly to market shifts.

-

Transparency: AI-driven insights make it easier to track sustainability metrics and ethical sourcing, important for modern consumers.

-

Innovation Image: Leveraging AI shows customers and partners you’re investing in the future. If your production process reflects innovation and reliability, your brand automatically benefits.

How AI Is Used in Manufacturing Today

Many manufacturers have already adopted AI in meaningful ways. From shop floor operations to logistics, AI is redefining how factories function. It’s helping businesses automate routine tasks, predict maintenance needs, reduce downtime, and respond faster to customer demands.

Key Use Cases

-

Predictive Maintenance Using AI in Factories: AI monitors equipment conditions and usage patterns to predict failures before they happen. This reduces downtime, saves on costly repairs, and keeps production running smoothly.

-

Artificial Intelligence in Quality Control Systems: High-speed cameras combined with AI algorithms can detect defects faster and more accurately than human inspectors. This helps maintain high standards without slowing down the line.

-

How AI Is Used in Manufacturing for Scheduling: AI helps balance workloads, adjust to order changes, and prioritize tasks based on real-time data, improving agility.

-

AI Solutions Provider for Manufacturing: Instead of building everything in-house, many companies turn to AI solutions providers who specialize in manufacturing-specific tools and integration.

The Role of AI Consulting in Manufacturing Transformation

Many manufacturers struggle with questions like

-

Where do we even begin with AI?

-

What technology stack do we need?

-

How do we connect AI tools with our existing systems?

That’s where AI consulting becomes critical. AI consultants guide you through the journey, from identifying opportunities to deploying the right tools.

What AI Consultants Do for Manufacturers

-

Assessment: They start by evaluating how my current operations work, how ready my data is, and where AI can make the biggest impact. This helps identify quick wins and long-term opportunities.

-

Strategy: Based on that assessment, they build a clear, step-by-step plan for how and where to use AI — whether it's in production, quality control, maintenance, or supply chain management.

-

Integration: They connect AI tools with my existing systems, like ERP, CRM, and factory equipment, so everything works together smoothly and data flows without disruption.

-

Training: They guide my team through the new processes, making sure we understand how the AI tools work and how to use them in our daily operations without confusion.

-

Support: After everything is up and running, they don’t just walk away. They continue to monitor how the system is performing, make improvements, and fine-tune AI models as the business evolves.

Partnering with a trusted AI solutions provider helps me avoid costly trial-and-error mistakes, speeds up implementation, and gets me to real results such as lower costs, better efficiency, and stronger ROI much faster.

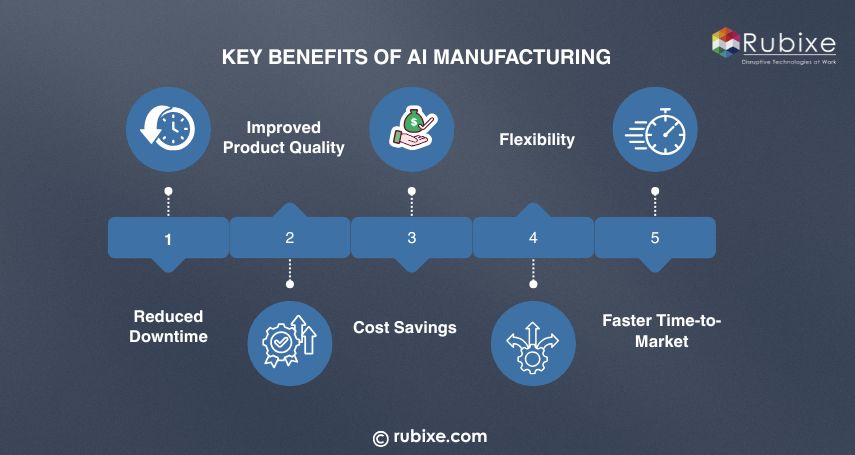

Key Benefits of AI Manufacturing

Still wondering if the investment is worth it? Here’s how AI can transform your production line and overall business strategy:

-

Reduced Downtime: Predictive maintenance helps identify issues before they cause breakdowns, keeping machines running smoothly.

-

Improved Product Quality: AI systems can detect defects in real time, ensuring consistent quality and fewer reworks.

-

Cost Savings: Automation reduces manual labor, minimizes errors, and cuts unnecessary operational costs.

-

Greater Flexibility: AI makes it easier to adapt quickly to new product designs or changes in customer demand.

-

Faster Time-to-Market: Intelligent scheduling and planning tools help speed up production cycles and delivery timelines.

-

Informed Decision-Making: With real-time insights and data analytics, you can make smarter business choices and lower the risk of costly mistakes.

How to Get Started with AI Manufacturing

Getting started with AI doesn’t mean you have to transform your entire factory at once. In fact, starting small is often the smartest and most cost-effective path. By working with the right partner, you can focus on one high-impact area, see real results, and build from there.

That’s where Rubixe comes in. With deep expertise in AI and a strong understanding of manufacturing challenges, Rubixe is the perfect partner to guide your transformation—from strategy to execution.

Steps to Begin:

-

Start with a Use Case: Choose one specific area where AI can make an immediate difference, such as quality control, predictive maintenance, or energy optimization.

-

Partner with Rubixe: Rubixe’s team will assess your needs, recommend the right solution, and ensure smooth integration with your existing systems.

-

Pilot the Solution: Begin with a small-scale implementation to validate performance and gather measurable data.

-

Evaluate the Impact: Rubixe helps you track KPIs like reduced downtime, improved quality, or cost savings to prove the value of AI.

-

Scale Gradually: Once you see results, Rubixe supports you in expanding AI across other parts of your operations with confidence and clarity.

AI manufacturing isn’t just about technology. It’s about building a smarter, more reliable, and future-ready brand. From improving quality to reducing downtime, AI helps businesses work better and deliver more value.

Getting started is easier with the right partner to guide the way.