Welcome to Rubixe, your portal to breakthrough AI solutions for manufacturing. We use artificial intelligence to alter industry operations, making production smarter, more efficient, and highly adaptive. Our AI-powered tools are designed to work easily with existing manufacturing systems, allowing companies to optimize operations, decrease downtime, and improve product quality.

Our solutions include predictive maintenance, quality control automation, supply chain optimization, and others. Each is built to solve the specific needs of the manufacturing industry and is supported by data-driven insights and real-time analytics. Whether you want to simplify your production line, enhance output, or reduce operational expenses, our AI technology can help.

Learn how We can assist you in realizing the promise of artificial intelligence in your industrial processes. Discover smarter methods to produce, develop, and grow using AI. Let us work together to construct the future of manufacturing.

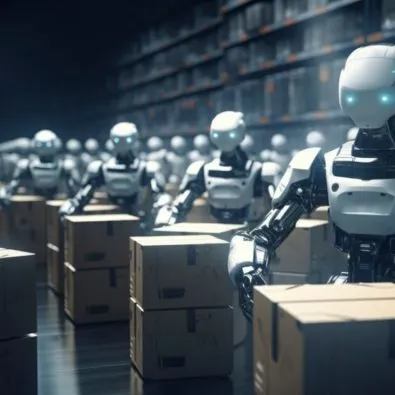

One of the primary applications of AI in manufacturing is automation. AI-driven robotic systems and machines can perform repetitive, labor-intensive tasks with remarkable precision and consistency. This not only reduces labor costs but also minimizes the risk of human error, ultimately improving product quality.

AI plays a vital role in predictive maintenance, ensuring that machines and equipment remain in optimal condition. By analyzing data from sensors and monitoring equipment, AI algorithms can predict when maintenance is needed, reducing downtime and preventing costly breakdowns.

AI systems equipped with computer vision technology can inspect products for defects and anomalies more accurately than human operators. This technology can rapidly detect imperfections, helping to maintain high product quality standards.

AI enables manufacturers to optimize their supply chains by predicting demand, managing inventory, and streamlining logistics. This results in reduced operational costs and more efficient distribution of products.

AI manufacturing uses intelligent systems to improve production quality, reduce downtime, and support better decision-making across factory operations. It helps teams monitor machines, manage workflows, and detect issues earlier. Smart factory AI tools also support automation, planning, and quality checks. Many manufacturers rely on AI to increase reliability and reduce waste. This makes operations more consistent, predictable, and easier to scale across multiple plants and production lines.

AI improves production efficiency by analyzing machine data, predicting delays, and identifying bottlenecks in the assembly line. It supports workload balancing, better scheduling, and smoother movement of materials. Smart factory AI systems can recommend faster routes for tasks or detect points where output slows. This helps teams make adjustments before production is affected. The result is a more stable manufacturing flow with fewer interruptions during busy or high-volume periods.

Predictive maintenance uses AI to read vibration patterns, temperature, and sensor alerts to detect early wear in machines. A large automotive manufacturer used AI predictive models across more than 100 robotic stations and avoided over 1,000 hours of unplanned downtime in a single year. These insights help teams schedule repairs at the right time and reduce emergency interventions. AI also helps extend equipment life and keep lines running more reliably

Yes, AI improves product quality by detecting defects that are hard to see with manual checks. A global electronics plant used AI vision systems to scan micro-components and reduced faulty units by over 300,000 parts annually. AI quality control tools compare thousands of images or measurements to find even the smallest variations. This results in fewer returns, more consistent production, and stronger trust in the final product delivered to customers.

AI helps manufacturers plan inventory, predict stock needs, and reduce material shortages. By analyzing order history, supplier behavior, delays, and demand fluctuations, AI creates more accurate plans. It also highlights slow-moving materials or possible disruptions. Companies use these insights to manage warehouses, plan transport routes, and reduce excess storage costs. This creates a more reliable supply chain that supports timely production and smoother coordination with vendors.

The team handled a complex project with tight deadlines exceptionally well. Their dedication and motivation ensured the project was delivered successfully. Great technical knowledge, flexibility, and teamwork made the experience smooth and efficient. - Catalin Bobeica, Senior Manager, Dell Inc.

Rubixe's expertise in AI-driven solutions has transformed our test case analysis, streamlining processes and enhancing product quality with remarkable efficiency. Their professionalism, dedication, and innovative approach not only met but exceeded our expectations, proving them to be a valuable partner in technological innovation. We're looking forward to further collaborations. - Cisco.

Exceptional AI expertise, delivering outstanding results. I highly recommend their services for anyone seeking top-notch AI solutions. - Thushara.