How AI Improves Inventory Management

How AI inventory management improves efficiency with AI tools, AI analytics, AI tracking, AI forecasting, AI optimization, AI supply chain, and AI data.

Why does inventory always feel like a risk instead of a resource?

Too much stock ties up cash. Too little costs customers. And spreadsheets rarely explain what’s actually coming next. With demand shifting faster, product cycles shrinking, and supply chains under pressure, guessing is no longer sustainable. AI inventory management changes this by helping businesses see demand earlier, plan more accurately, and make decisions with confidence.

Why Inventory Management Feels Broken for So Many Businesses

-

Static forecasts and manual planning: Decisions are based on past data and delayed reports.

-

Disconnected systems: Inventory, sales, and supply data remain siloed.

-

Human judgment under pressure: Teams make critical calls without full visibility.

-

Overstocking and stockouts: Cash gets locked up while customers walk away.

-

Reactive decisions: Problems are addressed after they occur.

-

Limited visibility: Businesses lack a clear view across locations and channels.

What Makes AI Inventory Management Different?

AI inventory management goes beyond tracking stock levels; it learns why changes happen and anticipates what comes next. Instead of looking only at past sales, it identifies emerging patterns in real time and adjusts inventory decisions accordingly. By combining historical and live data, AI replaces slow, manual processes with faster, more accurate planning.

How AI Inventory Management Actually Works

-

Sales Transactions: Tracks what sells, when, and at what pace.

-

Customer Behaviour and Demand Patterns: Identifies buying trends and shifts in preference.

-

Supplier Lead Times: Accounts for delays, variability, and reliability.

-

Seasonal Trends: Adjusts inventory for predictable demand changes.

-

Promotions and Pricing Changes: Reflects how offers impact demand.

-

External Factors: Considers weather, events, and broader market shifts.

Smarter Demand Forecasting Without Guesswork

Demand forecasting has always been one of the toughest inventory challenges. AI doesn’t remove uncertainty, but it significantly reduces blind spots by learning from past sales and live demand signals, spotting subtle trends, and adjusting predictions as conditions change. This allows businesses to plan inventory ahead of demand shifts rather than reacting after the damage is done.

Inventory Optimisation That Protects Cash Flow

-

Reducing Excess Inventory: Lowers overstock without increasing the risk of stockouts.

-

Improving Inventory Turnover: Ensures products move faster through the supply chain.

-

Balancing Safety Stock Levels: Maintains the right buffer based on real demand and risk.

-

Aligning Purchases with Demand: Matches buying decisions closely to actual sales patterns.

Faster, More Accurate Replenishment Decisions

Manual replenishment often depends on fixed rules and delayed reports, leading to rushed decisions. Artificial Intelligence inventory management makes replenishment intelligent and responsive by automatically adjusting reorder points, accounting for lead time variability, and learning from supplier performance. As a result, replenishment becomes continuous rather than periodic, reducing last-minute orders, emergency shipping costs, and operational stress.

Multi-Location Inventory Without the Chaos

-

Providing Real-Time Visibility: Gives a clear, up-to-date view of stock across all locations.

-

Enabling Intelligent Reallocation: Moves inventory between sites based on actual demand and availability.

-

Supporting Localised Forecasting: Adjusts predictions to reflect regional buying behaviour.

-

Responding Faster to Demand Spikes: Identifies location-specific surges and reacts before shortages occur.

How AI Inventory Management Reduces Human Error

Even experienced planners can make mistakes under pressure, and AI is designed to support, not replace them. By flagging anomalies early, highlighting risks, removing repetitive calculations, and providing data-backed recommendations, Artificial Intelligence inventory management frees teams to focus on strategic decisions instead of constant firefighting.

Real-Time Visibility Builds Confidence Across Teams

-

Real-Time Inventory Visibility: Always know current stock levels across locations.

-

Early Shortage Warnings: Identify risks before stockouts occur.

-

Clear Decision Explanations: Understand the logic behind inventory recommendations.

-

Confidence to Act Quickly: Make faster decisions without second-guessing.

Where Businesses See Immediate Impact

Artificial Intelligence inventory management delivers measurable results across industries. Retailers see fewer stockouts and markdowns with higher customer satisfaction, manufacturers reduce material shortages and production delays, e-commerce businesses improve fulfilment rates and order speed, and distributors optimise warehouse use while lowering holding costs. These improvements compound over time as AI systems continue to learn and refine decisions.

The Hidden Advantage: Speed

-

Detecting Demand Shifts Early: Spots changes before they show up in traditional reports.

-

Responding Faster Than Competitors: Enables quicker adjustments to purchasing and allocation.

-

Reducing Reliance on Monthly Cycles: Supports continuous planning instead of periodic reviews.

-

Turning Inventory into a Strategic Asset: Uses stock data to support growth, not just operations.

Why AI Alone Isn’t Enough Without Strategy

Technology alone doesn’t guarantee success. AI must align with business goals, data readiness, and day-to-day operations. That’s where experienced AI consulting makes the difference. Successful Artificial Intelligence inventory management depends on clean, connected data, clear use cases tied to outcomes, scalable systems that integrate with existing tools, and strong governance and security. Without this foundation, even the most advanced models fall short.

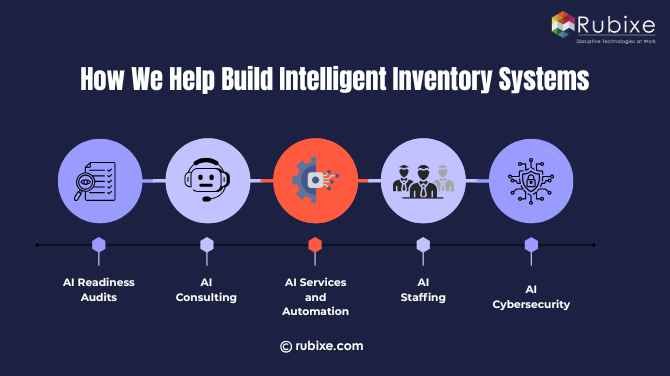

How We Help Build Intelligent Inventory Systems

-

AI Readiness Audits: Assess data quality, system capabilities, and gaps to ensure a strong foundation.

-

AI Consulting: Define the most impactful inventory use cases aligned with business goals.

-

AI Services and Automation: Deploy scalable solutions that integrate seamlessly into operations.

-

AI Staffing: Provide the right team to support implementation and ongoing growth.

-

AI Cybersecurity: Protect sensitive operational and inventory data from risks.

Trust, Transparency, and Responsible AI

AI readiness audits evaluate data quality, system capabilities, and gaps to build a strong foundation. AI consulting identifies the most impactful inventory use cases aligned with business goals, while AI services and automation deploy scalable solutions that integrate seamlessly into operations. The right AI staffing supports implementation and ongoing growth, and AI cybersecurity ensures sensitive operational and inventory data remains protected.

Common Myths About AI Inventory Management

-

“It’s only for large enterprises” - AI scales for mid-sized and growing businesses, delivering measurable value without requiring massive teams.

-

“It replaces planners” - AI augments human expertise, handling routine tasks while freeing planners to focus on strategic decisions.

-

“It’s too complex to implement.” - With a clear roadmap, AI can be deployed efficiently and start delivering results faster than expected.

The Future of Inventory Is Predictive, Not Reactive

Inventory management is no longer about reacting to shortages or excess; it’s about anticipating change. Artificial Intelligence inventory management shifts businesses from reactive planning to predictive intelligence, from static rules to continuous learning, and from guesswork to confident decisions. Early adopters build resilience, while those who delay struggle quietly.

Inventory isn’t just an operational function it’s a strategic lever that drives cash flow, customer trust, and growth. AI inventory management helps businesses see clearly, act confidently, and scale sustainably. In an uncertain market, intelligence is the strongest advantage, and the time to move beyond spreadsheets and manual planning is now.